You can use many tricks and tips to make your tablesaw work efficiently. Some of these tricks include using push sticks, keeping the fence aligned, and making sure the blade is at the right depth. These tips are based upon experience and can improve your cutting performance. You can find these and many more tips in this article. Remember to practice! After reading this article, you'll be a pro! No matter what material you are cutting, you will be amazed at the number of options available to you!

Push sticks

A great way to increase the safety of your work while using a table saw is to make use of push sticks. The ones you find in the stores can break apart and fall apart when the blade strikes them. You should instead choose one made from ABS plastic or nylon with fibers. Avoid aluminum push sticks because they can throw flak back at the blade. Instead, choose one that is at minimum 1/4 inch thick.

Blade depth

The blade depth of a table saw should be measured in millimeters. This measurement is not required. The CPSC staff reviewed all data and concluded that the voluntary standard had no effect on safety. Here are some key parameters to remember when choosing a saw for your table. The blade depth should not exceed 4mm below the skin's surface. The blade's depth should not be exceeded. Also, consider the dimensions of the saw, including its length and width.

Fence alignment

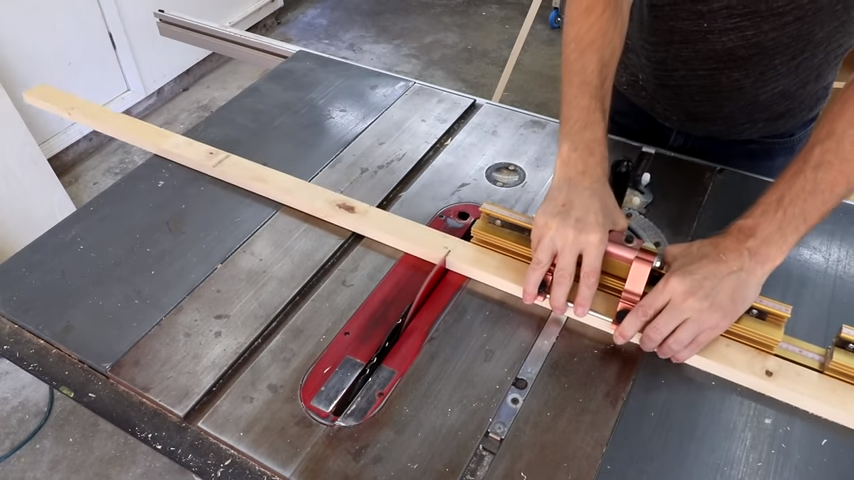

Regularly check the fence alignment when operating a tablesaw. You must align the fence within 15 to 20 percent of your blade's depth. This is why it is so important to check the alignment of your table saw's fencing frequently. Aligning your table saw's fence properly is essential for obtaining great cuts. You can use scrap wood, feeler gauges or a solid measuring instrument to do this. Just bring the fence within a few inches of its blade and then measure it with a feeler gauge. To make sure it's aligned correctly, place a feeler gauge along the blade's teeth and measure its distance.

Bridle joints

Bridle joints can be used for many types of woodworking projects. A bridle join has several advantages: strength, ease in machining, and a finished finish. This joinery is not often used in furniture. Another example of this is the mortise and tenon joint. To make a Bridle Joint, first you need to create a mortise on one wood piece and a tension on the other. After you have created the tenoning joint you can glue the pieces together.

Outfeed jig

Outfeed tables are a great way for you to expand your workspace's flexibility, regardless of whether you're starting a DIY or remodeling an existing tablesaw. To make an outfeed table that can be used with a larger table saw, for example, mill miter slots on the stand of your outfeed tables. Then, you can install an outfeed jig on it to help you adjust the height of your table saw.

Blade guard

These are some Blade Guard table saw tips to help you keep your fingers safe when cutting wood. First, imagine the cut's trajectory. To avoid kickback, do not place your hands in awkward positions. This can cause the blade's to grab the workpiece before you complete cutting it. Crosscutting is another option that allows you prevent the workpiece becoming stuck against the blade. Practice this technique regularly to make sure you're always one step ahead.

Dust collection

There are many options when it comes to dust collection for table saws. Whether you are building a cabinet, completing a home renovation, or simply cutting wood, dust collection is essential. A dust collection system should be fitted to your table saw's dust port. These systems capture the majority of sawdust produced during work, keeping your work area clean and healthy to breathe. Unlike a regular vacuum cleaner, table saw dust collection systems are made from heavy-duty fabric and have a sturdy zipper. The best table saw dust collection bags will collect as much as 70% of the dust generated by the machine.

FAQ

How do I choose the right tools for me?

It's important to consider your preferences and needs when buying tools. Do you prefer metal handles or plastic? What size screws and nails do you use most often? Do you prefer to use hand tools or power tools?

How do you calculate woodworking prices?

It is essential to calculate costs as accurately as possible when pricing any project. Always ensure you are getting the best possible price for materials. It's also worth taking into account all the other factors that may affect the cost of your projects, such as time, skill level, and experience. Our guide to the average household DIY task price will give you an idea of how much it costs to complete different types of woodwork projects.

How much do hobbyists need to invest in starting a business?

To start your own woodworking company, you will likely need capital to purchase the necessary tools and other supplies. It's a good idea to buy a small tablesaw, drill press and circular saw. These items are affordable so you won’t break the bank.

How do you know which type of wood you are working with?

When purchasing wood, always check the label. The label should provide information about the wood species, moisture content, and whether preservatives have been used.

Statistics

- Most woodworkers agree that lumber moisture needs to be under 10% for building furniture. (woodandshop.com)

- Overall employment of woodworkers is projected to grow 8 percent from 2020 to 2030, about as fast as the average for all occupations. (bls.gov)

- If your lumber isn't as dry as you would like when you purchase it (over 22% in Glen Huey's opinion…probably over 10-15% in my opinion), then it's a good idea to let it acclimate to your workshop for a couple of weeks. (woodandshop.com)

- The U.S. Bureau of Labor Statistics (BLS) estimates that the number of jobs for woodworkers will decline by 4% between 2019 and 2029. (indeed.com)

External Links

How To

Tips on how to drive a nail in wood

The first step in driving a nail into wood is to choose the correct size and type of hammer. There are many types of hammers that you will find: claw hammers and sledgehammers; mallets; ball peen hammers; and hatchets. Each kind of hammer has its own advantages and disadvantages. A claw hammer works well when you're trying to hit nails with a heavy hammer. However it is difficult to precisely control where the blow hits. A sledgehammer is great for hitting large areas at once, but it's too heavy to use effectively for smaller tasks.

After selecting the right hammer, you will need to place your hand flat against one side of the head. The handle should rest comfortably in your hands. Grab the handle tightly, but do not squeeze too hard. Hold the hammer straight up, keeping your wrist relaxed. You should then swing the hammer straight up, keeping your wrist relaxed. You should feel the impact on the nail from the hammer. If you're having trouble getting the hang of swinging a hammer, practice with a block of wood until you get the rhythm down.

Once you are ready to drive the nail, place the hammer close to your body. To ensure that the nail is perpendicular on the surface of the wooden floor, position it. Keep your eyes on the tip. Swing the hammer forward, then follow through with the motion of the hammerhead. Keep doing this until you are comfortable with the swing. Try adding power to your swings when you've mastered the technique. To make it more powerful, hold the hammer up high to your shoulder and then bring it down. You'll have more energy to work with.

Once you've made the first nail hole, take out the hammer. The rest of the nails can be pulled out using a screwdriver, pry bar, or a hammer. Keep the nails heads in line with the surface of the board to prevent splitting the wood.